Strengthen Productivity with Precision

In the dynamic business environments, making flexible and efficient production and capacity decisions are no longer optional, they are essential. Traditional approaches often fall short when faced with evolving customer demands and rapid market shifts, leading to inefficiencies and missed opportunities. To navigate this complex landscape, businesses need a robust production & capacity decision process.

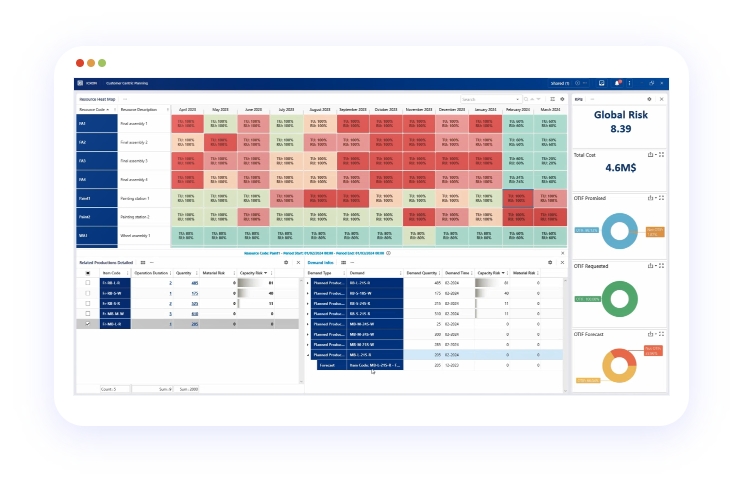

ICRON Production & Capacity equips businesses with the data-driven insights and capabilities needed to thrive in the ever-evolving marketplace. It optimizes production decisions for maximum efficiency, ensures robust utilization of capacity, and streamlines inventory management for seamless operation.

Let's dive into how ICRON Capacity & Planning benefits your organization with improved operations, optimized decision-making, and long-term sustainability.

Make informed decisions through mid to long-term production and capacity plans for each product level, starting from supply of raw materials to the satisfaction of customer demand.

Manage your capacity plan through flexible and multi-objective optimization management to cover all business goals considering all possible resource and BOM alternatives.

Track and manage opportunities regarding to production plan, stock allocations, and capacity engagement through continuous opportunity search mechanism.

Integrate factory calendar and unavailability rules to simulate resource capacity via the supply chain digital twin. Gain control over resources by managing capacity with easy modification options.

Integrate a comprehensive approach to supply chain resource planning, including renewable, consumable, and complex resources.

Have access to resource utilization data, encompassing total utilized capacity, regular and over-time usages, and other relevant metrics using capacity management.

Optimize inventory and production processes by employing a comprehensive material requirement planning with optimal bucket-based BOM selection.

Find the best possible balance between customer demand, resource utilization, and inventory levels to improve customer satisfaction.

Instantly assess the impact of material purchases and resource unavailability on production decisions to proactively manage the possible disruptions.

ICRON Production & Capacity is equipped with cutting-edge technological features that empower your organization to optimize its supplying capability and capacity at all strategic, tactical and operational levels, facilitating efficient and informed decision-making.

Resource Capacity & Bottleneck Management

Parametric Multi-objective Optimization

End-to-End Production Plan Visibility

Elevate Your Capacity and Production Management

ICRON Production & Capacity empowers your organization to excel in planning, ensuring resource optimization, a leading market position, and sustained competitiveness.

Let's ConnectICRON Demand empowers businesses to navigate uncertainty through accurate forecasting using AI-driven methods that take into consideration historical data, reaTime updates, and fast adaptation to changing market conditions and disruptions.

READ MORE