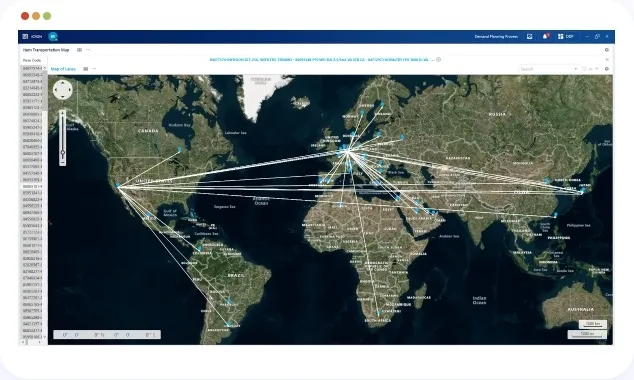

ICRON Supply Chain Network Design offers advanced modeling and simulation capabilities, combined with AI-driven analytics and scenario planning, enabling you to make informed, strategic decisions about facility placement, transportation routes, inventory flows, and more, based on your customer needs, cost considerations, market dynamics, and growth ambitions.

Key Features That Make ICRON Network Design Unique:

- Use a digital twin to model disruption scenarios, test strategic decisions in real time, and build flexibility while minimizing risk — all without impacting daily operations.

- Optimized inventory levels across plants, warehouses, and distribution centers — with configurable shelf-life and safety stock controls for perishable, seasonal, and high-margin SKUs.

- Advanced data modeling with ERP connectivity, custom-defined fields, and flexible time horizons (daily to yearly).

- Model your network with time-phased cost considerations, including inventory holding cost, transportation costs, and warehouse establishment cost.

- Get the ability to run varied scenarios to mitigate risk or exposure to economic shifts such as tariffs and trade agreements.

- Optimize your choice of transport mode by balancing cost, flow restrictions, shelf life, and speed, to ensure a smooth, efficient flow across your supply chain network.

- Regulatory and compliance support through country-specific registration calendars, batch/version tracking, and product eligibility enforcement.

Benefits

Reduction in inventory holding costs

Reduction in stockouts

Reduction in transportation costs

Reduction in lead times

*Typical outcomes reported by customers. Results vary by industry, constraints, and planning horizon.

You Need ICRON Network Design if You Are

Strategic Planners modeling future growth, disruption response, and investment scenarios

Operational Planners needing visibility into capacity, inventory, and transportation constraints

Supply Chain Managers optimizing cost-to-serve and evaluating flow paths across the network

Compliance or sustainability officers tracking emissions, waste, and regional policy requirements

Executives making informed decisions on trade-offs between cost, service, risk, and sustainability

How ICRON Network Design Drives Results

Holistic, Customer-Centric Configuration

ICRON captures the complexity of your operations and maps them against customer expectations. The result is a balanced, right-sized network that supports on-time, in-full delivery with minimal waste and maximum responsiveness. Includes brand/pack-level modeling, regional customer and product hierarchies, and service-tier segmentation.

Scenario-Based Resilience Planning

Leverage simulations to stress-test your network. Analyze the impact of demand shifts, cost changes, supplier losses, or geopolitical changes, and identify the most robust configuration under each scenario. Greenfield and what-if scenario tools allow you to test new market entry, network reshoring, or regional clustering strategies.

AI-Driven Trade-Off Insights

Advanced algorithms uncover optimization opportunities across your supply chain. Model the trade-offs between cost, service, and sustainability to make the best decision, not just the easiest one. Includes CO2 emissions tracking per transport mode, cost-to-deliver by lane, and automated scenario-driven recommendations.

Sustainability by Design

Model the environmental footprint of your network, including emissions, packaging, and mileage. Optimize for greener outcomes by favoring local sourcing, modal shifts, and consolidated shipments—without compromising service or cost targets. Align with ESG goals while tracking regulatory compliance and green logistics metrics.