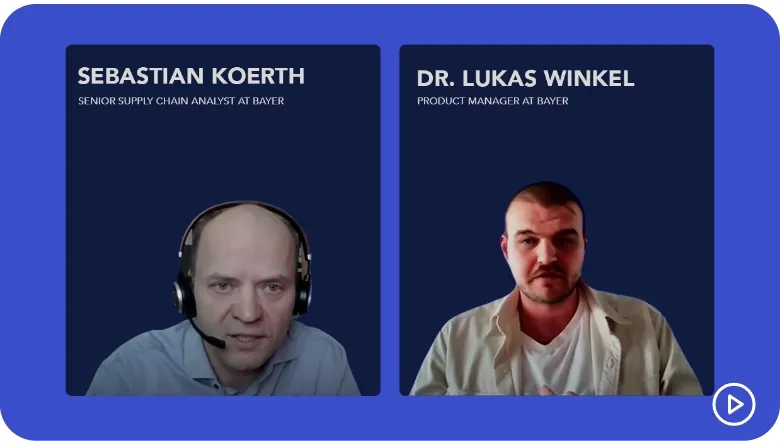

Customer Perspective Webinar: Network Design in Practice

In this webinar, supply chain leaders from Bayer share how decision intelligence and AI are applied to supply chain network design and multi-echelon inventory optimization using enterprise planning software. The session shows how supply chain network design decisions are evaluated across 15-year strategic horizons, 3–5-year tactical planning windows, and 2–3-year inventory horizons, aligning strategic and tactical planning layers to manage demand volatility, capacity constraints, and risk.

What it delivered: Clear identification of future capacity bottlenecks across the full pharmaceutical supply chain, more feasible launch plans evaluated on a monthly, scenario-driven basis, and safety stock levels calibrated through multi-scenario risk simulations (including downtime and disruption). ICRON enabled consistent, resilience focused decisions across strategic and operational planning layers while balancing service levels, capacity utilization, and risk exposure.