StarGrup is a frontrunner in the global glass manufacturing industry. With unparalleled expertise in producing custom glass products for both interior and exterior applications, they have a major presence in the global market. They partnered with ICRON to optimize their custom glass production process and enhance efficiency in manufacturing. With ICRON Capacity Planning, Production Planning and Scheduling, StarGrup achieved a 75% reduction in production planning time and 60% lower process waste besides improving on-time delivery capabilities and attaining higher customer satisfaction.

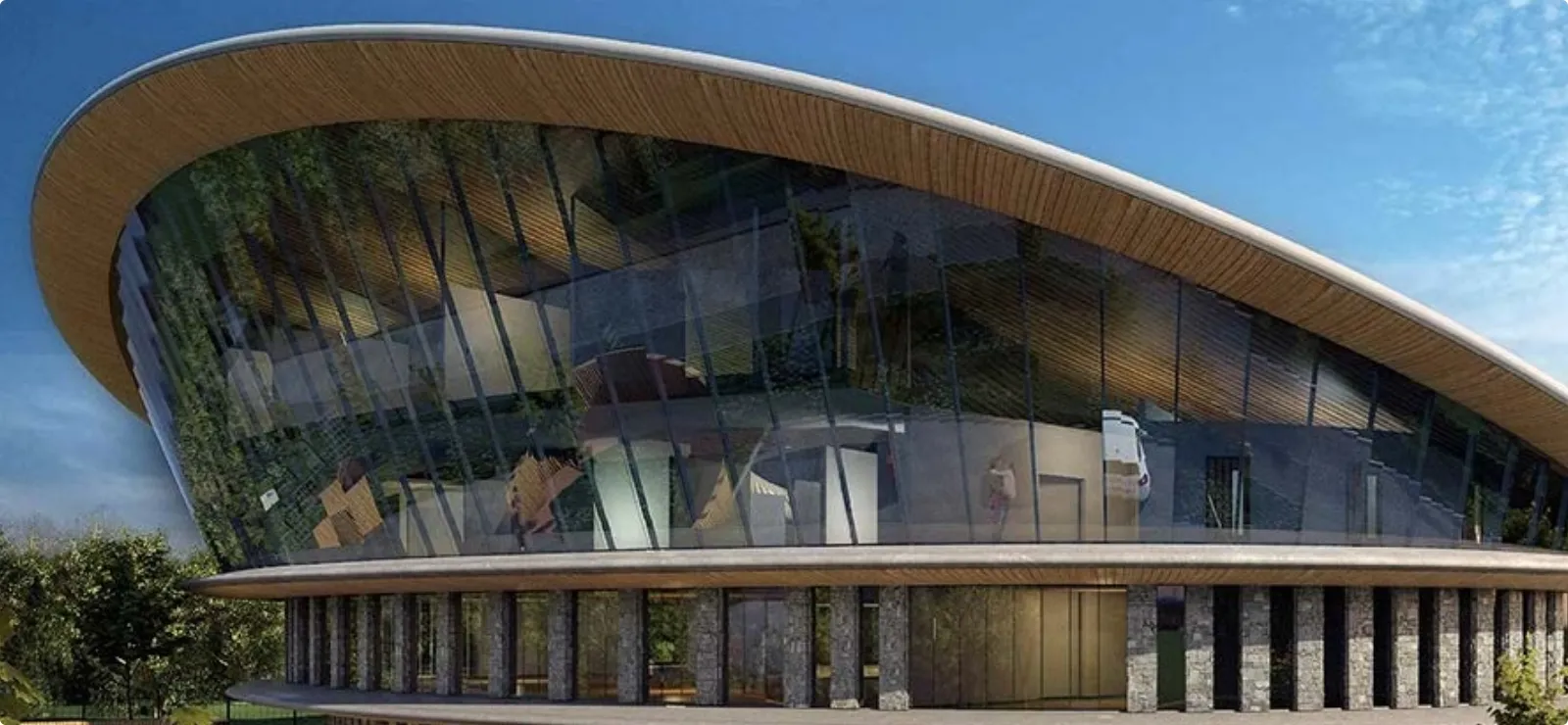

StarGrup is renowned for its tailored glass solutions. A multinational organization operating out of four global hubs, and with activities over 40+ countries catering to a wide range of customer needs – StarGrup was looking for innovative solutions to enhance efficiency and agility in their rapidly expanding supply chain. To maintain market leadership, it needed to meet complex customer specifications for grand-scale projects like shopping malls, apartment towers, and luxury residences with uncompromising precision.

Here’s a look at StarGrup’s primary goals

The glass manufacturing process is rife with complexities. From sourcing raw materials from global suppliers to managing the logistics of high temperature production and energy demands, there is considerable potential for internal disruptions. One of StarGrup’s primary goals was to develop a planning process that lent better flexibility and agility to its supply chain, enabling it to deliver on time without exception.

As StarGrup continues to expand their global supply chain, it was essential to increase operational efficiency to control costs, reduce energy waste, and optimize inventory management. StarGrup was focused on finding effective solutions to ensure timely delivery of raw materials and minimize production delays.

Supply chain success is intricately linked to the efficiency and agility of an organization’s planning processes. StarGrup relied on manual planning processes, which started to constrain its operations and did not offer a competitive edge. StarGrup aimed to upgrade to an AI-enabled advanced planning solution that was easy to scale up with business growth.

On-Time Delivery

The glass manufacturing process is rife with complexities. From sourcing raw materials from global suppliers to managing the logistics of high temperature production and energy demands, there is considerable potential for internal disruptions. One of StarGrup’s primary goals was to develop a planning process that lent better flexibility and agility to its supply chain, enabling it to deliver on time without exception.

Enhancing Overall Operational Efficiency

As StarGrup continues to expand their global supply chain, it was essential to increase operational efficiency to control costs, reduce energy waste, and optimize inventory management. StarGrup was focused on finding effective solutions to ensure timely delivery of raw materials and minimize production delays.

Streamlining the Planning Process

Supply chain success is intricately linked to the efficiency and agility of an organization’s planning processes. StarGrup relied on manual planning processes, which started to constrain its operations and did not offer a competitive edge. StarGrup aimed to upgrade to an AI-enabled advanced planning solution that was easy to scale up with business growth.

StarGrup’s core strength—delivering top-quality, customized glass products—heavily strained its supply chain, requiring every order to have a new production route and tailored requirements. This increased complexity and slowed operations.

Customers demanded delivery within 7-10 days, creating pressure for planners to deliver accurate schedules and meet expectations.

Managing hundreds of customer orders daily with distinct specifications stretched resources thin, leading to bottlenecks and operational inefficiencies.

Planners relied on spreadsheets, spending at least three hours daily on tedious scheduling. This inefficiency delayed decision-making and added stress to the team. Overwhelmed by the complexities of their customer-centric internal supply chain and the tight time constraints, planners at StarGrup needed a solution that would enable the optimization of decision-making processes – and for this, they turned to ICRON.

Unique Projects, Unique Strains

StarGrup’s core strength—delivering top-quality, customized glass products—heavily strained its supply chain, requiring every order to have a new production route and tailored requirements. This increased complexity and slowed operations.

Tight Deadlines

Customers demanded delivery within 7-10 days, creating pressure for planners to deliver accurate schedules and meet expectations.

High Complexity

Managing hundreds of customer orders daily with distinct specifications stretched resources thin, leading to bottlenecks and operational inefficiencies.

Manual Planning Limitations

Planners relied on spreadsheets, spending at least three hours daily on tedious scheduling. This inefficiency delayed decision-making and added stress to the team. Overwhelmed by the complexities of their customer-centric internal supply chain and the tight time constraints, planners at StarGrup needed a solution that would enable the optimization of decision-making processes – and for this, they turned to ICRON.

ICRON helped StarGrup’s planners move beyond manual guesswork, giving them the ability to build accurate, optimized daily production schedules. It resulted in better use of resources, smoother operations, and fewer last-minute surprises.

With advanced capacity planning tools, StarGrup gained the visibility and confidence to scale production in line with future demand — without over committing resources.

By connecting directly with the MES, ICRON ensured planners always had up-to-date shop floor insights at their fingertips — no more chasing information or relying on outdated numbers.

Through seamless integration with Lisec, ICRON helped StarGrup align cutting plans with schedules, minimizing waste and ensuring production ran like clockwork.

By integrating with Axapta, ICRON bridged the gap between production planning, inventory, and demand — keeping every part of the business on the same page.

ICRON set up a reporting infrastructure that gave planners and leadership real-time visibility into KPIs, helping them track performance, spot trends, and make smarter decisions faster.

Overall, implementing ICRON’s solution significantly improved the flexibility and efficiency of StarGrup’s production process, enabling the manufacturing firm to fulfill its promise to customers to deliver premium, customized glass products on time. Operationally and financially, ICRON’s solutions have yielded tremendously positive results for StarGrup, including:

75% reduction in production planning time

Increase to 95% on-time delivery

79% reduction in semi-finished goods stocks

60% reduction in process waste

10% reduction in raw glass stocks

10% increase in workforce efficiency

75% reduction in production planning time

Increase to 95% on-time delivery

79% reduction in semi-finished goods stocks

60% reduction in process waste

10% reduction in raw glass stocks

10% increase in workforce efficiency

Partnering with ICRON has been nothing short of transformative for StarGrup. Their Advanced Planning Solutions have reshaped our production process, driving a remarkable 75% reduction in production planning time and a 95% surge in on-time delivery. We have slashed process waste by 60%, allowing us to respond faster and more effectively than ever. ICRON’s cutting-edge tools have streamlined our operations, eliminated bottlenecks, and boosted our on-time delivery performance—all while maintaining the exceptional quality our customers rely on. Thanks to ICRON, we are meeting and exceeding the market’s growing demands, solidifying our position as a leader in customized glass solutions.

ICRON Demand empowers businesses to navigate uncertainty through accurate forecasting using AI-driven methods that take into consideration historical data, reaTime updates, and fast adaptation to changing market conditions and disruptions.

READ MORE