Customer Centric Supply Chain Planning

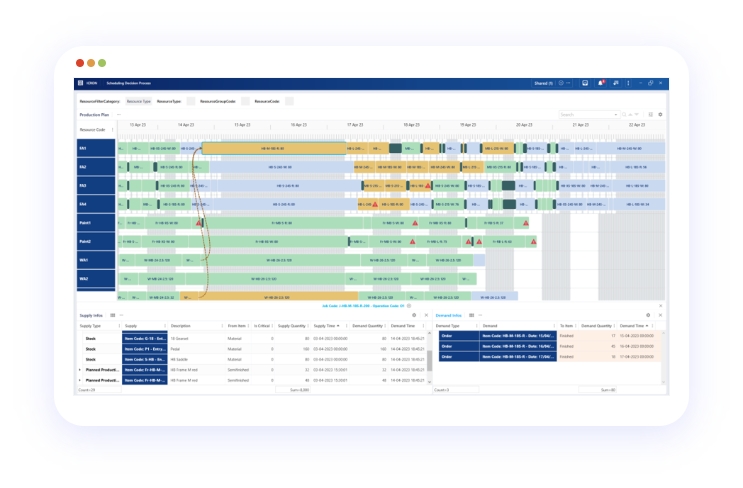

Production Scheduling

Schedule Smarter. React Faster. Deliver with Confidence.

Scheduling is no easy task. With countless alternatives, dynamic constraints, and competing priorities, it’s a complex decision process. You’re juggling productivity, capacity utilization, demand priorities, and tight delivery targets—all while navigating real-time disruptions.

That’s where ICRON Production Scheduling (Detailed Scheduling) steps in. Designed for agility, ICRON helps you take control of complexity. Whether it’s an unexpected machine breakdown, an urgent customer request, a shift in maintenance plans, or material shortages—it empowers you to re-schedule quickly and effectively.

With ICRON, you gain instant visibility into risks and opportunities as conditions change. That means smarter decisions, faster reactions, and a schedule that keeps your operations aligned with your goals.

Boost productivity. Maximize capacity. Stay on target. ICRON Production Scheduling empowers you with intelligent automation and real-time visibility, turning complexity into clarity and action.