At a Glance

Supply chain network design is a strategic lever for responding to market shifts, entering new markets, and balancing cost and service trade-offs across sourcing, production footprint, and distribution flows.

Network decisions increasingly need to reflect nonlinear constraints, geopolitical uncertainty, sustainability requirements, and volatile demand. Optimization is expanding beyond simple linear cost minimization toward approaches that can evaluate multi-objective trade-offs and uncertainty across scenarios.

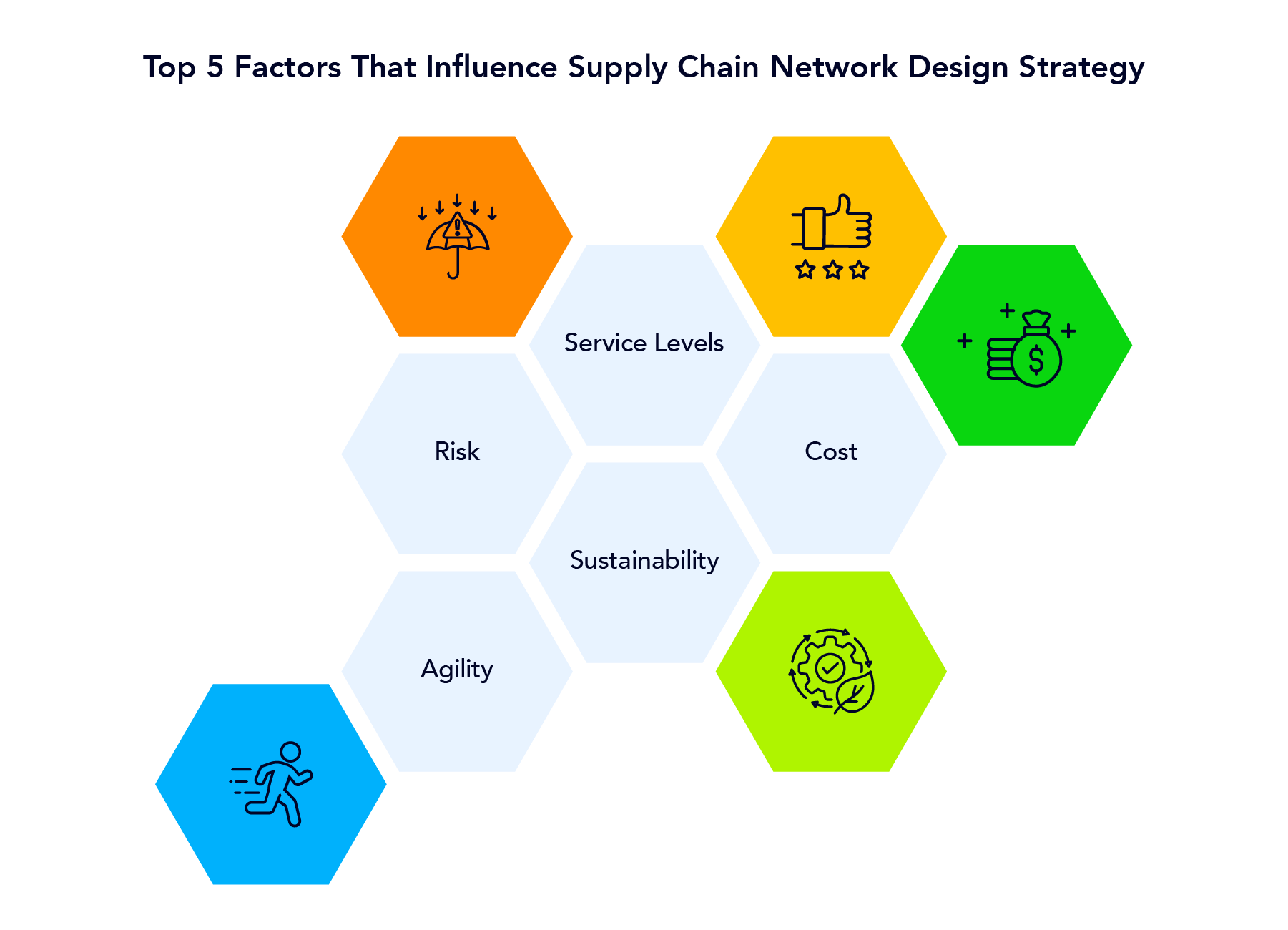

Core drivers include cost, service levels, risk & agility, and sustainability, supported by scenario-based decision-making, fit-for-purpose technology, flexible sourcing/production/distribution, and end-to-end visibility.

The Strategic Role of Network Design

A supply chain network is a strategic lever that determines the agility with which the supply chain can respond to market changes, expand to new markets, and balance cost and service trade-offs. Every significant decision – where to source, where to produce, and how to organize the product flow – can be traced back to the structural choices behind it.

While the fundamentals remain — facility locations, flows, and cost-service trade-offs — today’s designs must also contend with nonlinear constraints, geopolitical variability, sustainability mandates, and volatile demand. As optimization techniques evolve from linear programming to multi-objective and stochastic modeling, the ability to design not just for today’s business but for tomorrow’s scenarios becomes a competitive differentiator.

Top Contributing Factors in Network Design Strategy

Cost considerations play a pivotal role in supply chain network design. However, it is not the sole KPI that businesses prioritize when building the strategic design of their supply chain networks. Businesses today are expanding their focus to include a broader set of metrics, such as service levels, risk, reliability, and sustainability, as KPIs for network design. Let’s take a closer look at the contributing factors to supply chain network design.

-

Cost

Cost is the top contributing factor when designing your supply chain network. Network design requires modeling both direct and indirect costs, including total landed cost, cost-to-serve, and the implications of capacity utilization across global tiers. Beyond CAPEX and OPEX, planners today must incorporate cost volatility (e.g., fuel, tariffs, and costs associated with ESG-related activities) and translate financials into actionable design constraints.

-

Service Levels

Service levels are critical to customer satisfaction and experience. Although 83% of businesses prioritize enhancing customer experience through their digital supply chain strategy, [1] maintaining service levels is key to this ethos. Supply chains must differentiate service levels by customer segment, product criticality, and geography, rather than just meeting an average target. OTIF metrics, lead time variability, and differentiated fulfilment promises to require dynamic modelling. The challenge lies in balancing these service expectations with the realities of cost and inventory in real-time.

When designing a supply chain network, it is critical to strike a balance between cost and service levels. A well-designed network optimizes the trade-offs between inventory, transportation, and warehousing costs, while ensuring that service levels consistently meet or exceed customer expectations. Attaining optimal service levels can give your business a competitive edge, making it a significant KPI in network design.

-

Risk & Agility

Risk resilience is no longer an afterthought — it’s a design input. From dual-sourcing strategies to multi-modal transport networks, resilient networks must simulate failure modes and define mitigation paths. Planners are now using probabilistic models and digital twins to simulate disruptions and pressure-test responsiveness under real-world constraints.

Agility refers to a supply chain network's ability to model disruptions, anticipate them, and take quick actions to overcome disruptions and uncertainties without compromising customer experience, meeting demand, and fulfilling operational commitments. An agile supply chain network employs strategies such as redundancy, risk mitigation, and optimized network design to assess the impact of anticipated disruptions and simulate corrective actions in a timely manner, thereby enhancing customer satisfaction and operational resilience.

-

Sustainability

Sustainability is integral to the design of an optimal supply chain network, enabling supply chain leaders to assess the environmental and social impact of their business operations. In this context, sustainability includes minimizing the carbon footprint, reducing waste, and being socially responsible when designing and operating your supply chain. ESG, which stands for environmental, social, and governance principles, is a crucial factor in designing supply chain networks. Companies that prioritize ESG principles not only contribute to a more responsible ecosystem but also position themselves for long-term resilience.

While cost, service levels, risk, and sustainability remain core drivers of supply chain network design, the real challenge lies in optimizing these often-conflicting priorities in an increasingly volatile, complex, and constrained world. As global operations become more dynamic and customer expectations more demanding, designing a resilient and responsive network is a continuous strategic imperative. But getting it right isn’t easy. Let’s explore the key challenges organizations face in supply chain network design today.

What are the Biggest Challenges in Supply Chain Network Design?

-

Demand Volatility & the Bullwhip Effect

Uncertainty is a constant in supply chain planning, and every supply chain experiences significant shifts in demand, changes in market dynamics, and customer expectations. Often, we also witness minor changes in demand triggering a bullwhip effect, which results in overstocking or stockouts of inventory at various levels of the supply chain. Designing a supply chain network to minimize uncertainty can be challenging when you lack reliable forecasting tools to construct an optimal supply chain network that maximizes overall agility and responsiveness.

-

Uncertainty & Complexity of Global Operations

Multi-tier supply chains, with production and storage facilities worldwide, face increased risks and challenges. Quality and performance laws may vary from region to region, making regulatory compliance more challenging for global supply chain networks. Geopolitical and environmental issues can exacerbate the problem by creating unprecedented disruptions in the supply chain network. According to a recent survey by McKinsey, 64% of companies are regionalizing their supply chain network, making permanent changes to their network design in the process. And this number is rising every year. [2]

-

Striking a Balance Between Efficiency & Responsiveness

In supply chain design, the real challenge lies in striking a balance between efficiency and responsiveness. Efficiency drives cost reduction and speed, while responsiveness ensures the flexibility needed to navigate market shifts and disruptions. The struggle is not in choosing one over the other, but in integrating both into a network that is both cost-effective and adaptable. As businesses face unpredictable demand and evolving market conditions, finding the right equilibrium between these often-conflicting priorities becomes a critical challenge in maintaining a competitive edge.

-

Resolving the Speed vs. Budget Dilemma

Efficiency demands streamlined operations, consolidated facilities, and minimal excess — all in service of cost reduction and asset utilization. However, responsiveness requires flexibility, including maintaining a higher inventory level closer to the customer, diversifying routes, and maintaining capacity buffers to absorb demand volatility and disruptions. These goals often pull in opposite directions. A network optimized for efficiency may lack the agility to respond when a supplier falters or a market shifts overnight. Conversely, a hyper-responsive setup can carry excess costs and complexity that erode margins and exceed budgets. The challenge is particularly acute in industries where demand is unpredictable and product life cycles are short, and speed is as critical as efficiency. Balancing these competing imperatives is one of the toughest strategic decisions supply chain leaders face.

-

Analyzing Multiple ‘What-If’ Scenarios with Limited Planning Capability

The significance of scenario planning in supply chain network design is widely recognized. However, analyzing and planning multiple ‘what-if’ scenarios with limited planning and modeling capabilities, incomplete data, and outdated assumptions can do more harm than good. The sheer number of variables — lead times, demand shifts, supplier reliability, regulatory changes — creates a level of complexity that’s difficult to simulate, let alone optimize. As a result, network decisions are often made reactively or based on best guesses rather than rigorous scenario analysis. In a world where uncertainty is constant, this gap between aspiration and execution leaves organizations vulnerable — not just to disruption, but to missed opportunities.

-

Shifts in Trade Policy and Tariffs

Changing trade policies across the globe — including new tariffs, export restrictions, and industrial incentives — are forcing companies to revisit their sourcing strategies and production footprints. In many major markets, governments are reshaping trade flows to protect domestic industries, secure critical technologies, and respond to geopolitical pressures. These shifts are directly impacting total landed cost calculations and driving moves toward regionalization, supplier diversification, and nearshoring. For global manufacturers, tariffs and trade uncertainty have become critical inputs in network modeling scenarios, primarily when serving multiple regulatory environments and navigating cross-border complexity.

These challenges take different shapes across industries. A pharmaceutical company may focus on regional cold-chain hubs to ensure compliance and maintain optimal service levels. A high-tech manufacturer, by contrast, may need to factor in short product life cycles, high risk of obsolescence, and frequent engineering changes. In the food and beverage (F&B) sector, seasonality and perishability significantly influence location and logistics decisions. This is why network design is never one-size-fits-all — industry context shapes every decision.

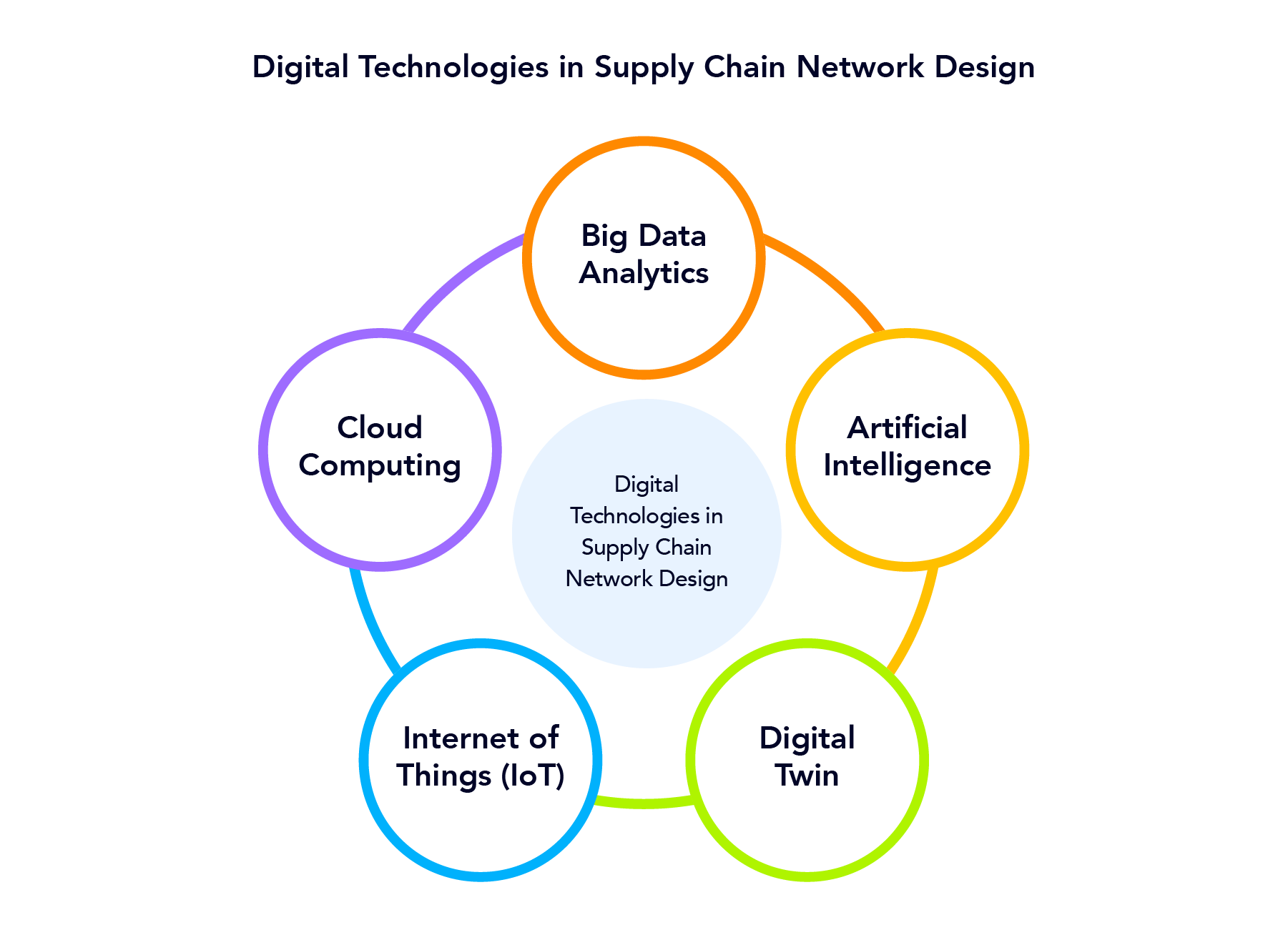

The Significance of Technology in Supply Chain Network Design

Recently, the Financial Times reported a survey by The Conference Board. Out of the companies surveyed, 34% intend to increase their use of artificial intelligence and planning solutions to enhance performance and tracking across the supply chain. [3]

Global companies are waking up to the reality that supply chain network design must be digitally enabled, continuously optimized, and rooted in data-driven insights. They are investing in advanced platforms that can model thousands of scenarios, evaluate cost-service trade-offs in real-time, and factor in multidimensional constraints. Artificial intelligence (AI) and machine learning (ML) remain at the core of this evolution, enabling planners to identify hidden patterns, forecast disruption risks, and make more accurate, dynamic decisions across the network. Here’s a look at some of the innovative technologies at the forefront of digital supply chain network design –

-

Big Data Analytics – Conducting a comprehensive analysis of large and complex data sets to draw valuable insights that enhance forecasting accuracy and strategic planning at every level of the supply chain. Deploying big data analytics in network design also improves visibility by applying predictive analytics to anticipate market trends and consumer behaviors.

-

Artificial Intelligence – Besides being leveraged for predictive analytics, demand forecasting, and automation, AI technologies play a significant role in enabling decision intelligence based on data-driven insights. AI/ML capabilities empower supply chain network design processes by streamlining operations and decision-making across the supply chain.

-

Digital Twin – A digital twin is a virtual replica of a physical supply chain network, enabling organizations to simulate, visualize, and analyze real-world operations in a risk-free, digital environment. By mirroring the entire network, digital twins provide a real-time, end-to-end view of network behaviour. This empowers planners to test scenarios, identify bottlenecks, and predict the impact of changes before implementing them.

-

Internet of Things (IoT) – A wide range of IoT assets can be integrated into a supply chain network to track, automate, communicate, and provide real-time advice. Empowered by cloud connectivity, IoT networks can help improve visibility, reduce manual tracking efforts, enhance operational control, and facilitate predictive asset management.

-

Cloud Computing – Cloud computing solutions facilitate the seamless collaboration of diverse supply chain activities and processes. With flexible and scalable data storage and processing, they enable global supply chains to create a single source of truth by enhancing collaboration and information sharing across the supply chain network.

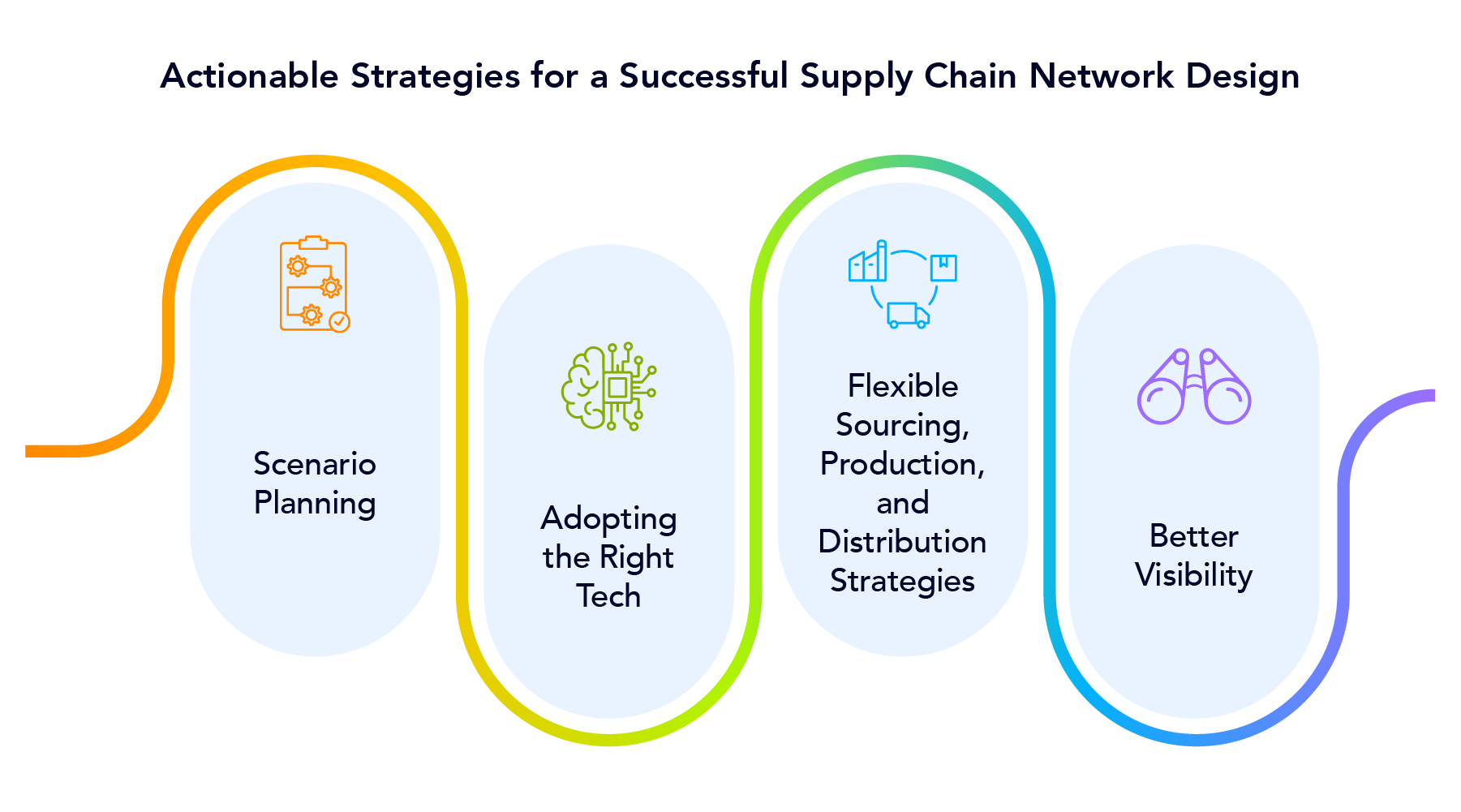

Actionable Strategies for a Successful Supply Chain Network Design

-

Scenario Planning – Scenario planning is a key decision intelligence tool for building responsiveness in supply chain network design. Collaborative scenario planning involves aligning stakeholders around shared assumptions and building flexible models that can test the impact of disruptions, regulatory shifts, or demand surges. This approach ensures that decisions are not made in isolation but reflect a comprehensive view of business risks and trade-offs.

-

Adopting the Right Tech – Technology is not a silver bullet; the effectiveness of a technological innovation depends on the fit between the tool and the need. Businesses that invest in the right technology, moving beyond spreadsheets and legacy systems to adopt solutions with advanced modelling, real-time analytics, and AI-driven decision intelligence, can thrive even in volatile markets.

-

Flexible Sourcing, Production, and Distribution Strategies to Combat Demand Changes - Designing a supply chain that can pivot quickly to meet shifting demand is crucial to staying competitive. This includes multi-sourcing critical components, building modular production capabilities, and maintaining regional distribution hubs that enable faster responses to local market changes.

-

Better Visibility - End-to-end visibility remains a cornerstone of effective supply chain network design. Visibility solutions — powered by IoT, control towers, and integrated data platforms — provide planners with the intelligence they need to proactively respond to disruptions, rebalance inventory, and maintain service levels across the network.

ICRON Supply Chain Network Design

Supply chain network design is not a one-time exercise, but a continuous strategic process that evolves in response to market demands, operational risks, regulatory changes, and sustainability goals. Organizations that succeed in creating optimal supply chain networks do so by embracing complexity, prioritizing data-driven decision-making, and investing in the right technology.

This is where ICRON’s AI-powered Supply Chain Network Design solutions come into play. With the capability to simulate, compare, and optimize numerous network scenarios in real-time, ICRON enables companies to model service level, cost, risk, and ESG impacts, all within a single, dynamic environment. Unlike many stand-alone tools, at ICRON we utilize the results to drive responsiveness and strategic direction within the organization throughout our full suite of planning solutions.

Whether you’re restructuring global production, expanding distribution, or preparing for market volatility, ICRON provides not just the design tools, but the connected intelligence to turn network models into responsive, organization-wide action. In a world where change is constant, your supply chain network must be anything but static. With the right approach and the right partner, supply chain network design can become a powerful lever for competitive advantage.

Get in touch today to find out how the right network design strategy can make a difference to your supply chain.

Key Questions in Supply Chain Network Design

What is supply chain network design, and why does it matter?

Supply chain network design defines where to source, where to produce, and how products flow through the network. These structural choices determine responsiveness, cost-to-serve, and the ability to adapt as conditions change.

Which factors drive network design decisions beyond cost?

Cost remains critical, while service levels, risk & agility, and sustainability increasingly shape network decisions as core performance dimensions.

Why are service levels a central KPI in network design?

Network structure directly affects lead times, fulfillment commitments, and the ability to differentiate service by customer segment, product criticality, and geography, not just meet an average target.

What does “risk & agility” mean in network design?

Risk resilience becomes a design input. Dual sourcing, alternative transport modes, and network options like regional buffers can reduce exposure. Simulation methods, including probabilistic modeling and digital twins, help test disruption impacts and mitigation paths.

How is sustainability incorporated into network design decisions?

Sustainability considerations can be embedded alongside cost and service, including carbon footprint reduction, waste minimization, and broader ESG requirements across design and operations.

What are the biggest challenges organizations face in network design today?

Common challenges include demand volatility and the bullwhip effect, global complexity and compliance constraints, balancing efficiency with responsiveness, speed vs. budget trade-offs, limited multi-scenario capability, and shifts in trade policy and tariffs.

Why is scenario planning so critical, and why is it difficult to do well?

Scenario planning reduces reliance on best guesses by testing assumptions under different futures. In practice, incomplete data, outdated assumptions, limited modeling capability, and too many variables often constrain scenario depth and speed.

How do trade policy shifts and tariffs affect network design?

Tariffs, restrictions, and policy incentives change total landed cost and can trigger network changes such as regionalization, supplier diversification, and nearshoring. Trade uncertainty becomes a critical input for scenario modeling.

Why is technology increasingly important in network design?

Continuous network evaluation requires digital enablement: fast scenario modeling at scale, clear cost-service trade-offs, and the ability to represent multi-dimensional constraints without oversimplifying the business.

Which technologies are highlighted as enablers for digital network design?

Enablers include big data analytics, AI/ML, digital twins, IoT, and cloud computing to strengthen insight, simulation, visibility, collaboration, and decision-making.

What actionable strategies support stronger network design decisions?

Collaborative scenario planning, fit-for-purpose technology beyond spreadsheets and legacy tools, flexible sourcing/production/distribution options, and improved end-to-end visibility.

How does ICRON fit into this Supply Chain Network Design story?

ICRON enables decision-driven network design by evaluating scenarios, constraints, and trade-offs across sourcing, production footprint, distribution flows, capacity, inventory, service levels, cost, risk, and sustainability objectives in a single environment. Teams compare feasible alternatives, quantify trade-offs, and turn network decisions into connected planning actions as conditions change.