Authors: Özgün Aydın from ICRON and Lieneke van Boxel from CQM

Predictive maintenance is a hot topic among executives from manufacturing to public transportation to mining to logistics. Predictive maintenance - also known as condition-based maintenance- can harness the power of IoT, data, and advanced analytics algorithms to monitor and gauge the condition of a company’s assets (such as production machines, airplanes, trains, trucks, and cranes) on an ongoing basis, predict precisely when these assets will need maintenance, and recommend the optimal time window in which to schedule and perform maintenance activities.

A growing number of companies are discovering that predictive maintenance-based planning and operations can enable them to minimize asset downtime and maintenance costs. Many of these companies are interested in implementing predictive maintenance strategies, tools, and technologies, but they don’t know how to make it happen.

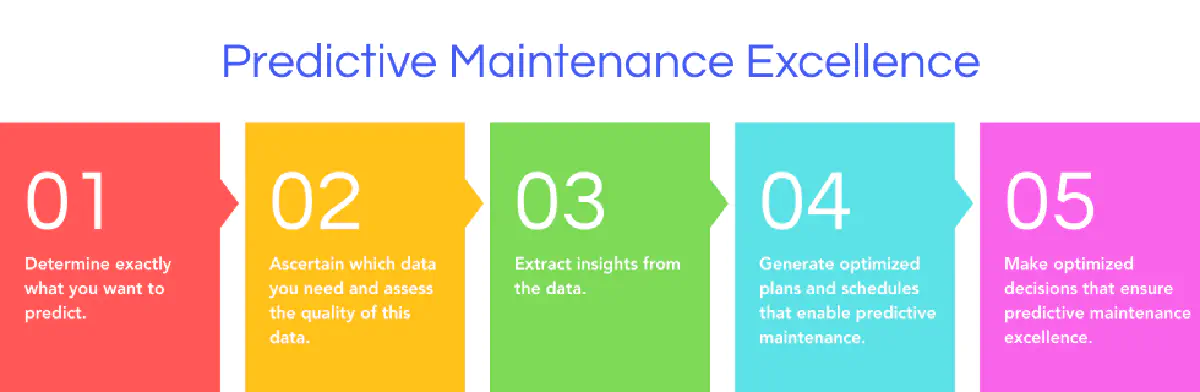

Here are five steps to reap the benefits of predictive-based maintenance planning and operations:

1. Determine exactly what you want to predict

As is the case when starting any project, it is imperative to clearly and precisely define the scope of the implementation of the predictive - based maintenance planning system as well as the goals of the initiative. One of the common pitfalls of these types of projects is that companies fail to determine exactly what they want to predict – and instead have only a vague, general goal of wanting to predict and prevent asset failures.

2. Ascertain which data you need and assess the quality of this data

The next step in implementing a predictive maintenance-based system is to collect historical and real-time data from various sources that are relevant and of the highest quality – including IoT devices, back-office systems (such as ERP, Excel, and MES), and web services – on the past performance, failure and maintenance history, and current condition of your assets.

3. Extract insights from the data

After collecting relevant data on the past and present performance of your assets, you will need to feed this data into a best-of-breed automated, algorithm-based planning and optimization system – like ICRON – that has a robust advanced analytics engine to turn them into actionable insights, projections, and plans.

4. Generate optimized plans and schedules that enable predictive maintenance

Fuelled by the data and advanced analytics, the algorithmic planning and optimization system will then automatically generate optimal maintenance plans and schedules for assets that:

- Optimize the timing and duration of your company’s maintenance activities,

- Take into account your assets’ past performance and current condition,

- Enable you to predict the future performance of your assets, perform preventive maintenance only when necessary, and prevent costly asset failures and breakdown.

5. Make optimized decisions that ensure predictive maintenance excellence

Beyond merely being able to create optimized maintenance plans and schedules, the goal of implementing an algorithmic planning and optimization system is to empower planners and key stakeholders in your company to make optimized decisions about the frequency and duration of future maintenance.

Furthermore, when unexpected asset breakdowns do occur (as they inevitably will) and corrective maintenance is necessary, your planners and other key stakeholders will be able to instantly, optimally revise your plans and make the right decisions to mitigate the potential impact of these disruptions on your operations.

ICRON can help your company to adopt predictive maintenance excellence to get the most out of your assets while reducing asset downtime and maintenance costs and improving customer satisfaction.

If you would like to see ICRON in action, please contact us. If you have enjoyed this blog, you can find more content that you might enjoy here.