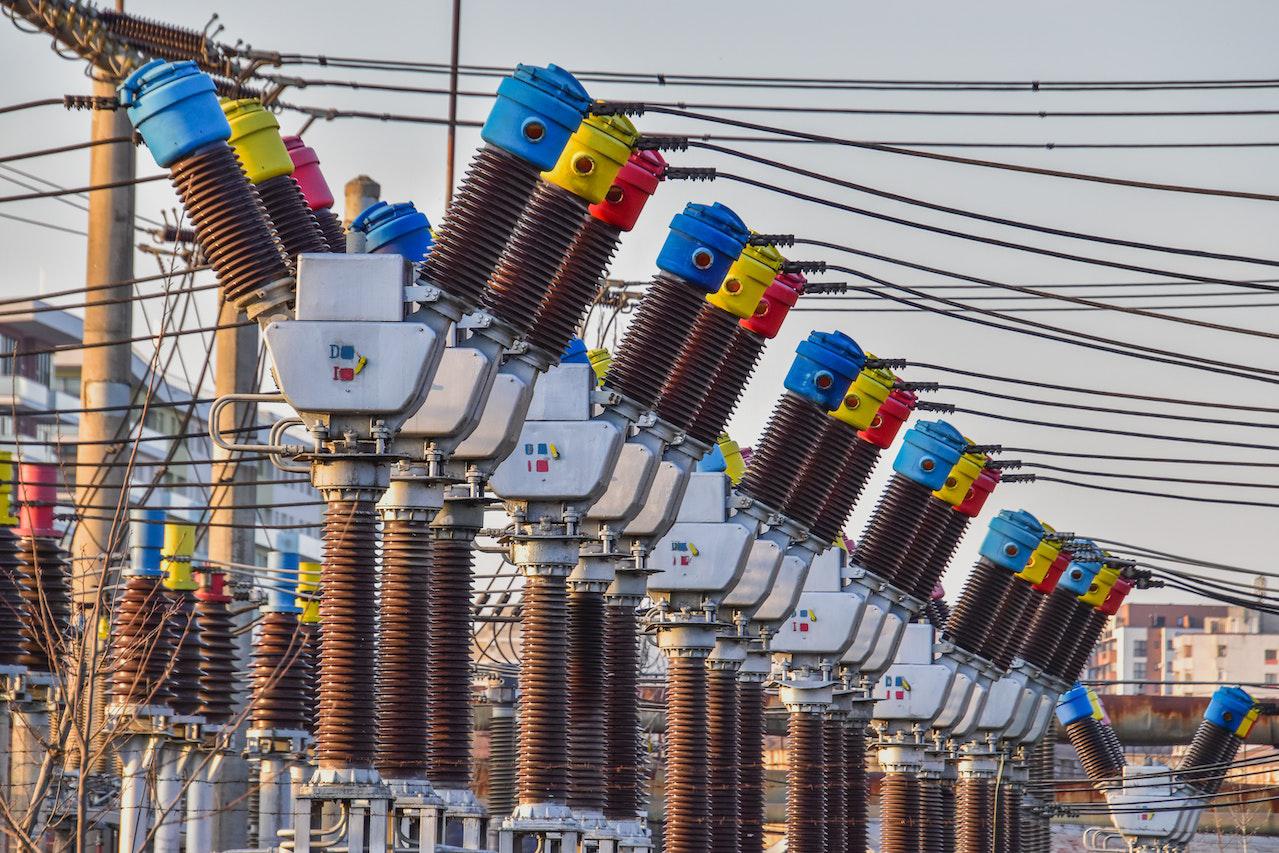

ICRON, a leading provider of Optimized Decision Making and Supply Chain Optimization software solutions, today announced the successful go-live of its new Advanced Planning & Scheduling (APS) solution at Balıkesir Elektromekanik Sanayi Tesisleri (BEST Transformer), a global leader in the electric machinery industry specializing in high voltage power transformers, reactors, oil immersed and dry type distribution transformer production. The implementation of ICRON’s APS solution by BEST Transformer marks a major milestone in the long-term business relationship between the two companies, which have been working together since 2009.

Over the past nine years, ICRON has been a key factor in the transformation and optimization of the production planning processes at BEST Transformer, which produces high voltage power transformers, reactors, oil immersed and dry type distribution transformer and mechanical components. After utilizing ICRON’s Capacity Planning solution for many years, BEST Transformer recently decided to implement ICRON’s APS solution to optimize its power transformer production planning process.

Nazmi Ziya Özgür, ICRON’s Lead Implementation Consultant, commented: “ We have been on a remarkable journey with BEST Transformer over the last nine years, and we are happy to see how we helped them to transform their production planning system. As a result of the implementation of ICRON solutions, BEST Transformer is now able to generate optimal plans that are aligned with the company’s capacity and material constraints – and this is a crucial factor when it comes to having a successful production line. There were also other constraints – process timings and routes were way too long, and there was too much assembling and disassembling required – which made the planning process even more complex and challenging. With ICRON, the BEST Transformer planning team is now also capable of managing all of these issues and able to create optimized productions plans.”

Mert Ertürer, ICRON’s Operations Director, said: “ We started to work with BEST Transformer in 2009, and we have come a long way together. We are really proud to be the driving force behind such a big transformation in BEST Transformer’s production planning process. We are talking about a huge difference here. We are talking about a company that previously used Excel files to track and revise their plans, which now has a fully automated and optimized planning process.”

Ayhan Çelik, Planning Manager at BEST, remarked: “ BEST, with our ever-expanding customer portfolio and increasing prominence in the global electromechanical sector, faces significant challenges when it comes to production planning. After attempting to implement a few other solutions and not getting the results we were hoping for, we started to work with ICRON and we could not be happier with the success we have achieved together. ICRON first demonstrated their knowledge and expertise in Capacity Planning, and now we are sure that we will have the same success with ICRON’s APS solution as well.”

About BEST Transformer

BEST is Europe’s largest independent transformer manufacturer based in Turkey. Operating in two facilities in Balıkesir, the company is operating in all major areas of transformer manufacturing, from the oil immersed distribution transformers to large GSU transformers. Company can produce any type of power transformer up to 800MVA and 750kV level. In recent years BEST also became one of the major players in special transformers market, with the current record keeping 310MVA arc furnace transformer, and the 180MVA 500kV Magnetically controlled shunt reactor, also the largest in the world. So called “special” because of their unique properties and applications, these type of product is generally regarded as a company’s mark of technical expertise and production quality.

The company embraced a policy of continuous improvement of both its product range and manufacturing capacity. In this spirit, BEST expanded its dry type transformer manufacturing capacity by building one of the world’s largest and most modern manufacturing facilities for this product.

BEST is currently manufacturing transformers as its one and only product, which allows them to focus on details. As an independent manufacturer, they enjoy the freedom to participate in projects with nearly all sub suppliers, contractors, and end users. The company is an active partner of power system utilities and users in over 50 countries. The same independence also helps faster decision making.

While it may seem narrow at first, transformer marketing, design, and production is extremely diversified. The final product could be anywhere from a few hundred kilos to hundreds of tons. The product itself also presents some unique challenges, as most power transformers are tailor-made to customer specifications; mass production possibilities are very limited. Materials and accessories required for assembly of parts from other suppliers, are also ordered specifically for the job at hand, meaning working from reserves are usually not an option. BEST factories employ over 1000 workers encompassing all stages of transformer manufacturing, including accredited test laboratories. Finally, sale, manufacturing, and commissioning durations are also variable, and can be anything from a few months to several years depending on size and scope of the project. Planning for such a production covering all of these diverse requires to combine precise planning but also a large degree of flexibility.

For more information please contact: hello@icrontech.com