In the new normal, uncertainty and resilience have become the basics of the revolution of the global supply chain. Meanwhile, evaluating risk and adopting strategies to increase customer satisfaction while minimizing costs that have been increasing due to disruptions have become inevitable. Even before the pandemic, numerous events in recent years have already temporarily disrupted production in many companies, the COVID-19 pandemic and crisis such as chip shortage have accelerated this even further. As a result, in these times of extreme uncertainty, adopting a customer centric approach has increased the resilience of supply chains.

According to research, conducted by Accenture, the top 90 supply chains have achieved 13% higher growth, three times higher contribution to total revenue. One of the differentiation points of top supply chain players compared to their peers is to start thinking with customers in mind. In other words, they build a supply chain strategy based on customer values. They are aware that meeting these changing customer expectations can make a significant difference, so they focus on the most important value propositions when investing in the supply chain. To establish growth, they adopt customer centric supply chain strategies.

Customer Centric Supply Chain in a Nutshell

Customer centric supply chains focus on the experiences of their customers in all supply chain operations to meet their demands. In other words, manufacturers focus on how they present their goods and services to the ever-changing market in addition to operational efficiency. They must be able to timely obtain, correlate and act upon demand requests to make decisions in planning, routing, and scheduling activities throughout the supply chain. This, in return, leads to an increase in customer lifetime value, customer satisfaction, and profitability while reducing churn.

Becoming a customer centric organization can be a complex and time-consuming process. However, if adopted, companies are empowered to focus on their customers and quickly adapt to meet changing customer needs, which make them gain adaptability and resiliency. One of the reasons why companies need adaptability is because the volatility both on the demand and supply sides is high. This requires companies to be more agile or, in other words, to increase their capability to change. In order to do so, companies need to gain visibility and understanding of the affected parts of their supply chains to be able to respond effectively and keep satisfying their customers.

In addition to customer satisfaction and increased responsiveness, a customer centric supply chain offers an operational environment where every decision maker within the organization

- has a clear comprehension of the impact of every decision on every single customer’s service level,

- and holds the pulse of end-to-end operational dependencies among different levels of the supply chain.

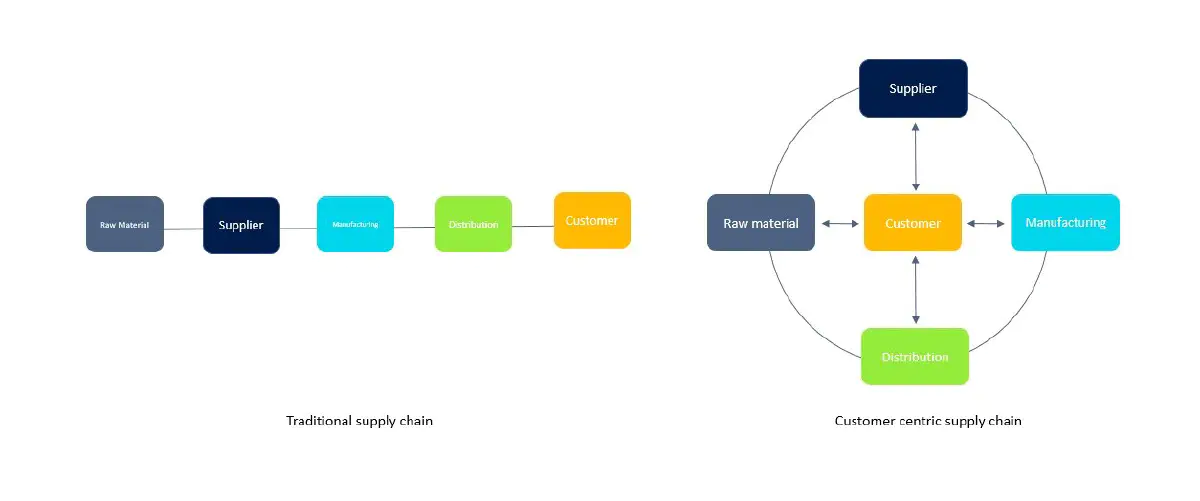

In traditional supply chain, customer is the end point while customer centric approach is influential for each step.

Customer Centric Approach to Supply Chain Planning

In a customer centric approach, planning activities should take risks and opportunities into consideration. These risks and opportunities should be considered in terms of customers: possibility of not providing the requested service to the customer on time (risk) or possibility of providing better service to the customer (opportunity).

As the volatility is high, it is vital to have insights into all changing situations related to the customers and their possible impacts on the operations. However, it’s not sufficient. The insights should be monitored instantly and projected on plannings to make proactive decisions. In other words, real-life insights that cannot be integrated into the data system need to be visible for resilient decision-making.

Order promising is planning delivery dates for customer orders by taking limitations into account. Customer centric approach considers risks on orders such as delivery, capacity or material while, if available, it seeks opportunities for extra production availabilities for new orders and early deliveries to provide better service to the customers.

Capacity planning traditionally is described as allocating resources in order to meet the demand. In a customer centric approach, companies can see and manage bottlenecks and utilization of resources. It enables a company to see instantly the effects of capacity decisions on customer orders and forecasts and manage risks accordingly.

Inventory planning, by description, aims to minimize inventory costs while reaching service level goals. However, cost minimization is only a small part of the problem. Minimizing inventory might not be the “right” decision every time; sometimes it’s necessary to increase the inventory levels to handle changing circumstances. In customer centric approach, sometimes it is possible not to minimize inventory costs to gain benefit from giving better service to customers, which can be projected at each inventory decision.

Detailed scheduling focuses on finding the optimal short-term production plan, considering resource and material availability. Customer centric detailed scheduling focuses on adapting operational decisions to recent real-life disruptions while gaining end-to-end visibility from shop floor to demand.

Demand planning aims to better forecast the demands by taking consumer trends, historical sales, and seasonality data into account. In relation with the customers and their orders, impact analysis is carried out if the operational capabilities can meet the forecasted demand in the customer centric approach.

Material supply planning calculates the material requirements with respect to orders and forecasts of end products and proposes optimal purchase orders. Customer centricity serves associating purchase decisions of materials to customer orders of end-products, analysing supplier effects on orders via risk management and enables responsiveness to possible disruptions.

Become Customer Centric with ICRON Customer Centric Supply Chain Planning

ICRON is designed with customer centric approach. It enables you to put customers at the heart of each decision-making to enhance customer satisfaction and profitability. You can gain control over your whole supply chain and become resilient.

If you would like to see ICRON in action, please contact us. If you have enjoyed this blog, you can find more content that you might enjoy here.