Author: Mine Kaçan

In my career at ICRON, which has spanned nearly two decades, I have had the opportunity to work with numerous customers around the world and across various industries. Although each company’s supply chain is different with its own unique dynamics, constraints, and complexity, I have observed that there are certain common challenges that all these businesses face. One of these is controlling costs.

Indeed, cost minimization is a main KPI of nearly every supply chain manager. The reason for this is clear: Supply chain costs constitute a huge (and often hidden) danger to the financial health and future of any company. If your company’s supply chain costs are not effectively monitored, managed, and optimized, they can eat away at your bottom line and – over the long haul – ultimately break your business.

Why is Cost Minimization Difficult?

Cutting costs sounds simple in theory, but in reality, it is an incredibly difficult undertaking due to the fact that:

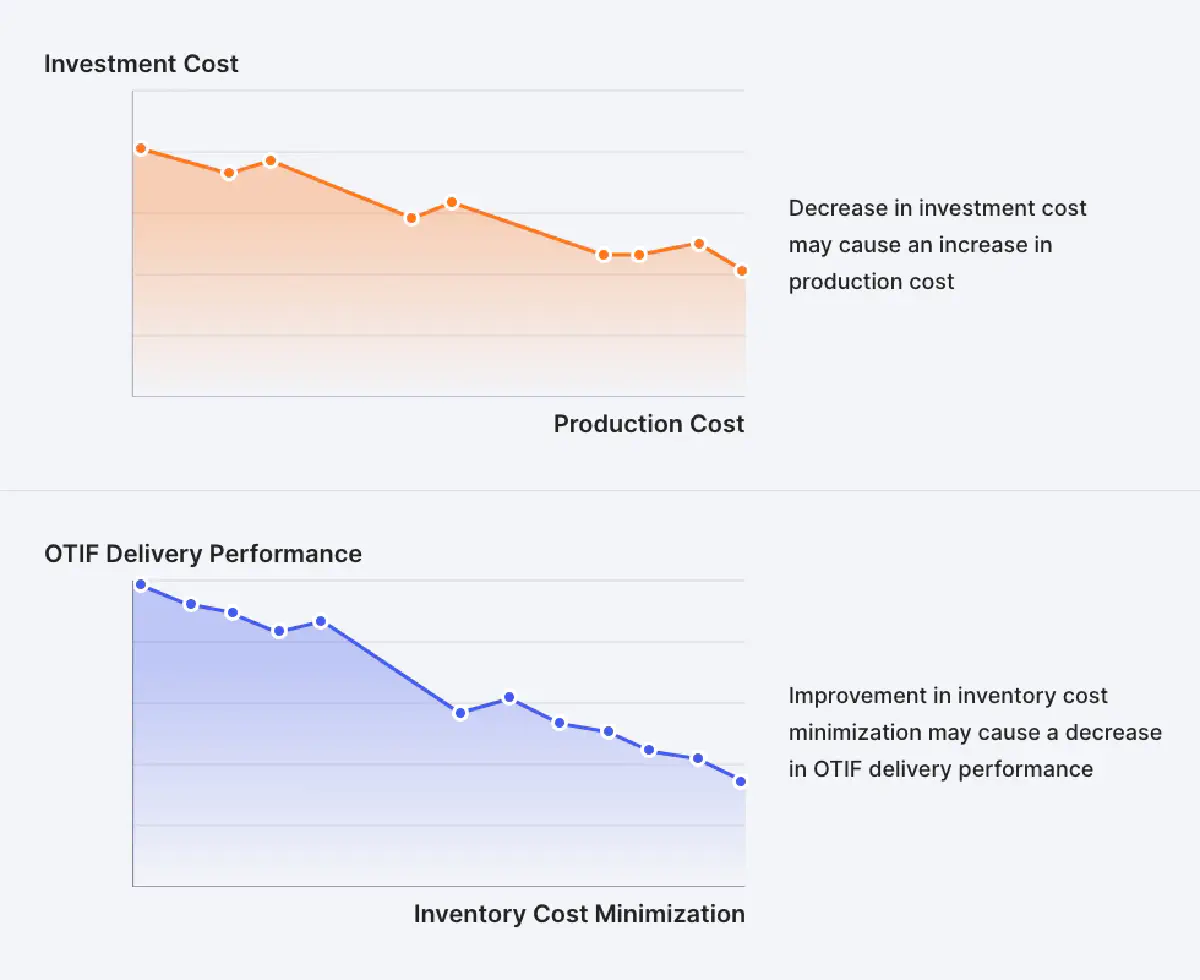

- The KPI of cost minimization is often in conflict with other KPIs such as revenue maximization, on-time in-full (OTIF) delivery performance, customer satisfaction, and inventory optimization. There’s always a tradeoff – as an improvement in one KPI may lead to a drop off in another.

- Supply chains today are highly complex and intricately interconnected, so a cost reduction in one area of operations can result in a cost spike in another. It is imperative to understand the interrelationship between various processes in your supply chain and the impact of slashing costs in one area on the entire supply chain.

- Senior supply chain executives are often hyper-focused on propelling revenue growth and fail to assess and address the effect of supply chain costs – which, if not curbed, can do great damage to profit margins over the long term. Many executives are not aware of the supply chain costs their companies are racking up, or the potential positive impact of even a small reduction in costs would have on their overall financial performance and competitive edge.

Due to these and many other factors, cost minimization is a tricky task for today’s supply chain companies, requiring tough decisions by key stakeholders. Before embarking on cost cutting initiatives, it is imperative to first determine the main supply chain cost drivers.

In this blog, we will take a look at what are the most significant supply chain cost drivers.

1. Investment Costs

In today’s globalized economy, most supply chains are sprawling multi-site networks of suppliers, manufacturers, distributors, and retailers that stretch around the world.

In this business environment, it is essential to make smart strategic decisions – over a time horizon of up to ten years – about where and when to invest in new facilities (such as warehouses and factories) and resources (such as equipment and employees).

Many supply chain companies pump too much money into the wrong locations at the wrong times or fail to invest in the right locations at the right times – and this can have a negative impact on their financial fortunes.

Managing investment costs and making sound strategic investment decisions is absolutely critical. To do this, your company must have:

- An end-to-end view of their supply chains (encompassing their entire network of customers, suppliers, manufacturers, distributors, and retailers).

- Accurate, data-driven demand forecasts for the coming five to ten years.

- A clear market strategy and expansion plans.

- The capability to correctly calculate current and potential investment costs across your supply chain and explore various “what-if” scenarios.

Getting a handle on strategic investment costs and making the best strategic investment decisions is crucial for your company to survive and thrive in today’s global economic landscape.

2. Transportation Costs

The second key driver of supply chain costs is transportation costs. Typically, the root cause of higher transportation costs – for finished goods as well as raw materials and components – is inefficient supply chain network planning, routing, and deployment of resources.

Managing investment costs and making sound strategic investment decisions is absolutely critical. To do this, your company must have:

- The design of your supply chain network to ensure the location of suppliers, manufacturers, distributors, and customers is optimal.

- The utilization of your capacity by, for example, adjusting load size or engaging third-party logistics (3PL) firms when extra capacity is needed.

- The routes and modes of transport (truck, airplane, ship, etc.) that you use for your orders – considering your capacity and constraints (and those of your 3PL services providers) as well as product-specific requirements.

- The selection of the suppliers, manufacturers, and distributors that you work with.

Many supply chain companies see their transportation costs skyrocket because they don’t have the capability to take all the above considerations into account, conduct scenario analysis to evaluate different options in terms of a transportation route, mode, and partner companies, and make optimized decisions on the best way to get their goods to their customers.

3. Procurement Costs

The third main contributor to soaring supply chain costs is procurement costs.

Choosing the right suppliers – who are consistently able to deliver the right products and materials at the right times and at the lowest prices – is vital. Choosing the wrong suppliers – who are unreliable or expensive – can cause your OTIF performance and customer satisfaction to plummet and your procurement costs to shoot up.

To minimize procurement costs, your company must be able to:

- Use historical and real-time data to evaluate and compare the performance and pricing of various suppliers.

- Choose the most reliable suppliers with the most competitive prices, who are able to deliver the goods you need (in the right quantity, of the right quality, at the right times, and in the right locations).

By optimizing your procurement process, your company can ensure that you make the best possible decisions when it comes to supplier selection, dramatically reduce procurement costs, and improve delivery performance.

4. Production Costs

Another primary source of supply chain costs – which applies to manufacturing companies in particular – is production costs.

Surges in production costs can be caused by various factors including:

- Inefficient utilization of assets such as production machines and other equipment. Many manufacturers are not able to assess their unit production costs (to identify which equipment and processes are inefficient) and weigh various production process alternatives and potential investment in new manufacturing technologies.

- Protracted machine set-up times – which, in turn, increase asset downtime and production lead times and decrease capacity.

- Ineffective workforce management, often results in a spike in overtime hours (and overtime wages that manufacturers must pay to employees).

- Rework, which is especially an issue for project-based or engineer-to-order (ETO) manufacturers. If each step of the manufacturing process is not performed correctly, extensive rework may be required – and this can involve repurchasing expensive raw materials and even restarting the whole manufacturing process from scratch.

- Various manufacturing overhead costs for items such as electricity, water, and equipment maintenance and repair.

To minimize production costs (while maximizing production efficiency and OTIF performance), manufacturing companies must be able to make optimized strategic, tactical, and operational plans and decisions.

5. Inventory Costs

The last major driver of supply chain costs is inventory costs.

Companies across the supply chain spectrum, from retailers to manufacturers to suppliers, rely on inventory as a buffer against supply and demand uncertainty and volatility.

Although inventory is undoubtedly a source of comfort for supply chain executives (as they can rest assured that they will always be able to satisfy demand), it is also a source of costs. Stockpiling and storing inventory can cause your costs – including warehousing and transportation costs – to shoot up and can tie up vital capital that could otherwise be used to propel your company’s growth.

It’s important to note that minimizing inventory costs does not mean eliminating inventory altogether – after all, some inventory is always necessary to fulfill customer demand. The goal here is to reduce excess inventory and to maintain just the right amount of stock of the right products in the right places at the right times across your multi-echelon distribution network.

Are you not sure how optimally you are managing your inventory levels? You may check our “4 signs that your company has an inventory management issue” blog to evaluate yourself in terms of inventory management. If you are suffering from the conditions mentioned in the blog, it means that you need inventory optimization as soon as possible to reduce your inventory costs.

The journey to cost efficiency

Now that you have had this crash course on supply chain costs, you are ready to embark on your company’s journey to cost efficiency, right? Not yet, actually…

It’s easy – as we’ve done here – to simply identify the main drivers of supply chain costs.

Minimizing supply chain costs is an incredibly challenging and complex endeavor. To achieve this, your company will need intelligent, integrated planning and decision making optimization solutions – like ICRON. With such a tool, you will be able to:

- Analyze your end-to-end supply chain using real-time and historical data as well as forecasts, projections, and “what-if” scenarios,

- Visualize your entire end-to-end network and accurately assess your costs in different areas (investment, transportation, procurement, production, inventory, and others),

- Develop an understanding of the interplay and interdependencies between your operations in these different areas and the impact of cutting costs in any one area on your overall operations and business goals,

- Optimally balance the tradeoffs between procurement, production, inventory, transportation, and other costs – taking into account OTIF performance targets, penalties for lateness, and other KPIs,

- And automatically generate strategic, tactical, and operational plans and make decisions that optimize your operations, minimize your costs, and maximize your productivity and profitability.

With ICRON, you can continuously measure, monitor, manage, and minimize costs across your supply chain and simultaneously achieve the highest levels of cost efficiency, operational excellence, and bottom-line performance.

If you would like to see ICRON in action, please contact us. If you have enjoyed this blog, you can find more content that you might enjoy here.